We sell a wide variety of materials & colours which are available with bespoke extrusion profiles.

Contact Us

What is plastic extrusion?

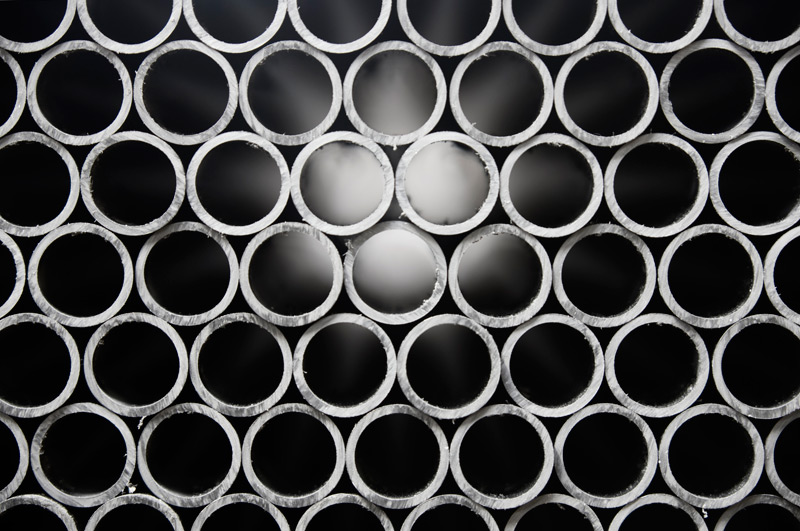

Plastic extrusion is a high volume manufacturing process which melts and shapes plastic raw material into continuous profiles.

What is it used for?

Typical plastic extrusion applications are piping, tubes, shelf edging, slatwell inserts, u channels for edge protection, j sections, poster grippers and capping.

Co-Extrude (or Dual Extrusion)

We co-extrude using both rigid and flexible pvc. Co-extrusion (or dual extrusion) is where two machines are used to extrude different types of plastic through a single die. Either to produce a profile with two colours or a combination of flexible and rigid material.

30 years experience

We have over 30 years experience of producing pvc extrusions. We design and make all of our own extrusion tooling and dies in-house using our Edm wire erosion machine. We can extrude rigid PVC, flexible PVC, ABS, Polyethelene & HD poly.

Benefits of using Peter Perks for plastic extrusion

Costs

Our customers find we are extremely competitive. Typically our minimum order is around £425.00. Tooling costs can vary relative to the complexity of the plastic extrusion profile.